QUALITY CONTROL

At Trakya Döküm, to meet and maintain the highest quality standards, modern quality control methods and quality management systems are utilized.

Being aware of the responsibilities and liabilities arising from our certifications, we closely monitor all processes from design to final product. During the processes and transitions between the processes, the products are regularly and continuously inspected according to well-established quality control criteria.

Metallurgical laboratories are used to determine metallurgical and mechanical properties during the melting and casting process. To ensure mould quality, automatic and manual moulding sand tests are also performed regularly. To verify the microstructural compliance of castings, the metallurgical laboratories utilize modern equipment. Fully automatic sample preparation unit and spectrometer analysis is available to enable fast and reliable metal composition analysis and high-volume production.

Also, all finished products are constantly inspected in Non-Destructive Testing and Dimensional Measurement Laboratories in order to ensure that the required physical requirements are achieved, and mechanical properties meet required criteria.

quality management systems

Working to the requirements of IATF 16949 standard as part of its strict quality system, Trakya Döküm understands the quality requirements of its customers.

At Trakya Döküm, in order to fulfil the requirements of all quality management systems we have, we constantly monitor and maintain our activities required for the continuous development and improvement of our integrated management system.

Methods for the achievement of continuous improvement include PFMEA, Lean 6 Sigma, Mistake – Proofing System (Poka-Yoke), Kaizen, TPM and 5S.

QUALITY CERTIFICATES

Our Policy

TRAKYA DÖKÜM QUALITY POLICY

It is to produce the products that ensure the satisfaction of the customers by applying total quality management, in accordance with the specifications and the prescribed standards (EN 10242 for fittings products), economically and to meet them on time.

Below principles will be applied in order to fulfill our quality policy. These principles are under the "commitment of management"

- Along with legal and regulatory requirements, customer requirements and expectations will be sensitively followed and fulfilled precisely.

- In our quality management system, IATF 16949 and ISO 9001 standards will be fully implemented. Necessary resources will be provided for the implementation of the quality management system.

- Target studies for “continuous improvement” will be conducted and will be reviewed periodically.

- Education will be given a strategic importance.

Our Policy

TRAKYA DÖKÜM CUSTOMER SATISFACTION POLICY

- Increasing customer satisfaction is our primary goal.

- Customer complaints will be committed to be resolved within targeted time-frames.

- Complaints are seen as opportunities to improve our products, processes and services.

- Prevention of re-occurrence of customer complaints is our top target.

- Training will be used to continuously improve and develop customer complaints management (CCM) activities throughout the organization.

- Trakya Dokum complies with all relevant Laws and Legislations regarding CCM.

Trakya Dokum is a customer oriented cast iron foundry, producing raw cast and machined products. Customer complaints management is carried out according to TS ISO 10002. Effective and efficient application of TS ISO 10002 has the full commitment and support of the senior management.

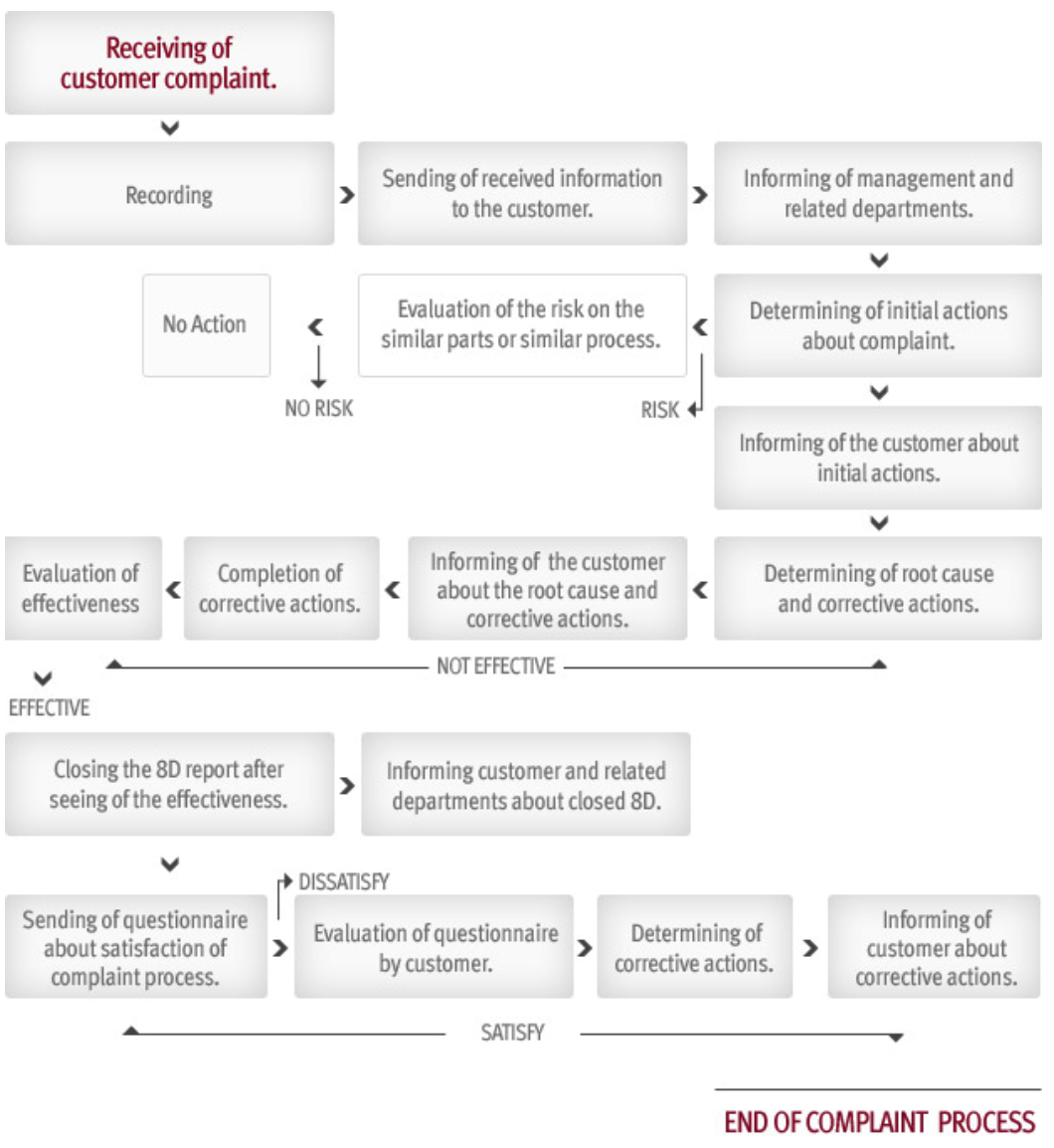

Customer Complaint Process

Contact

You can use the below conctact methods for your complaint notifications;

Mail :Tdf.KaliteHerkes@trakyadokum.com.tr

Tel : + 90 288 436 14 03

Fax : +90 288 436 10 49

Dear valued customer; complaint notifications are free of charge.

Our Policy

TRAKYA DÖKÜM ITMS POLICY

Information produced, used, archived and updated at Trakya Dokum is our most valuable asset. Information is our knowledge and it is essential to maintain and improve our production and service.It is fundamental to all our activities and for monitoring and achieving our strategic targets. Our information assets will be protected against all risks in terms of integrity, confidentiality and accessibility by applying ISO-27001 ITMS. This is included in our continuous improvement policy and ITMS is monitored by our top management.

SUPPLEMENTARY STATEMENTS FOR ITMS POLICY

- ISO-27001 ITMS will be improved with annual plans within the scope of management with strategic targets.

- Internal, external, physical and technological risks that threatens information security will be assessed and improved.

- ITMS is in compliance with international laws, regulations, customer requirements and Soyak Holding procedures.

- Competency and awareness of Trakya Dokum organization will be ensured by regular training programmes.

- ITMS policy will be reviewed once a year by the management.

Scope

ISMS in the scope of processes;

“Trakya Döküm San. ve Tic. A.Ş. Soyak Holding Binası, Büyükdere Cad. No: 38 Kat: 2 Mecidiyeköy- İSTANBUL” at the plant;

1.1. Accounting and Finance Process,

1.2. Marketing Process,

“Trakya Döküm San. ve Tic. A.Ş. Yeni Mah. D-100 Karayolu Cad. 1. Yan Sokak No:3 Büyükkarıştıran OSB Lüleburgaz KIRKLARELİ” at the plant;

1.3. Information Technologies Process,

1.4. Human Resources Process,

1.5. Quality System Process,

1.6. Physical Security Process,

1.7. Law Area Process,

1.8. Purchasing Process,

1.9. Pattern Manufacturing and Improvement Process,

1.10. Product Engineering Process,

1.11. Production (Foundry, Machining, Manufacturing and Core Production, Fittings Production) Process,

1.12. Sales, Logistic and Planning Process,

1.13. Maintenance Process,

1.14. Quality Process.